OPTIMISATION OF MAN'S MANUFACTURING PLANT INTERNAL LOGISTICS

MAN Truck & Bus Polska has carried out business activities on the Polish market for more than twenty years. MAN Trucks Sp. z o.o. operates a manufacturing plant located in Niepołomice near Kraków where heavy trucks are produced.

It is one of the most advanced truck assembly plants in the World, and the vehicles produced there are delivered to customers all over Europe. The manufacturing process is organized according to the just-in-time concept, and consequently component supplies to the production line are planned consistently with the production cycle and are completed using transport sets.

The MAN Trucks manufacturing plant in Niepołomice has used transport sets since its origins. Experience gained over the years of use of several systems enabled the plant management to set precise requirements for a new standard suitable for component logistics.

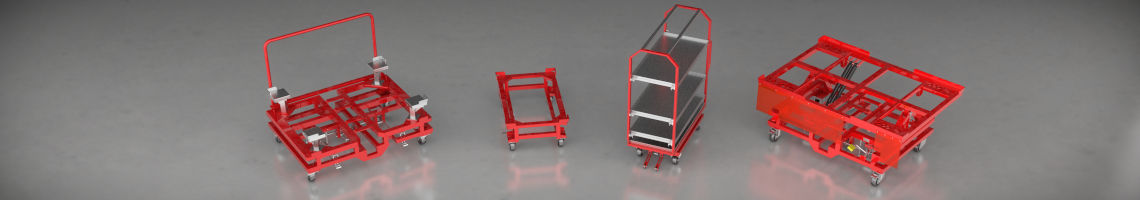

The main requirement for a design of new transport platforms was to integrate the trolleys commonly used in the manufacturing floor, with various dimensions, and weighing up to 500 kg. The identified areas of improvement included a reduction of noise generated by moving trains of transport sets, a reduced time dedicated to loading and unloading, better work ergonomics and eliminating undesired operating costs caused by accelerated wear of wheels and excessive expenses on maintenance of products based on hydraulic systems.

The MAN Trucks manufacturing plant entered into an agreement for project implementation with WAMECH, following successful initial operating tests of a standard version of the E-LINER® lean manufacturing production transport platform. Its fully mechanical design, intuitive and simple operation method as well as excellent traction properties provided a sound foundation for adapting this product.

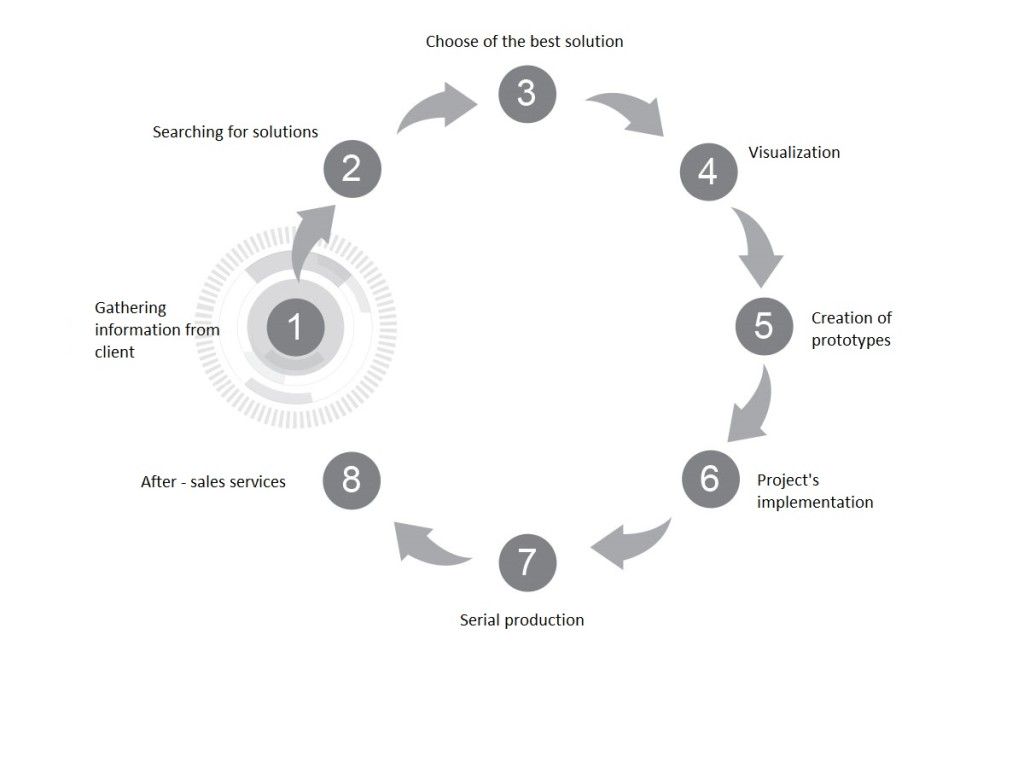

PROJECT'S IMPLEMENTATION - LEAN MANUFACTURING PRODUCTION

The project was implemented using an internal procedure developed at WAMECH for dedicated solutions. The procedure includes eight consecutive phases, beginning from input data gathering, prototyping phases and ending with after-sale service. Representatives of the MAN Trucks’ logistics division, working together with designers from WAMECH, using technical assistance provided by a Project Manager, developed a set of precise guidelines enabling the team to commence the project.

Following mutual consultations and an audit of previous solutions used at the MAN Trucks manufacturing plant, specific areas for optimization of the process then in use were distinguished and described, namely:

– a reduction of noise generated by moving trains of transport sets – the identified causes of noise included clearances between platform components, clearances between trolleys and platforms, containers hitting trolleys and trolleys hitting the floor during transport;

– reduced operating expenses on the trolley fleet – by preventing excessive wear of wheels caused by the method of trolley transport on platforms. The trolleys had contact with the floor during transport which, at a high speed, led to accelerated wear due to abrasion and mechanical damages. The scale of the problem was so large that the factory dedicated a warehouse space to wheel storage and appointed a team responsible for replacing wheels;

– reduced maintenance costs and a better availability of the platforms – the hydraulic wheel control system then in use required frequent, specialist and expensive maintenance. Aeration in the system, leaks and losses of alignment significantly reduced the availability of the equipment;

– a reduced time of necessary operations on platforms and improved ergonomics of use – the platforms equipped with “safety barriers” were inconsistent with ergonomic principles and time-consuming in use. An operator of the mechanism was required to bend and remember to close the safety device each time before a train of transport trolleys could be set in motion.

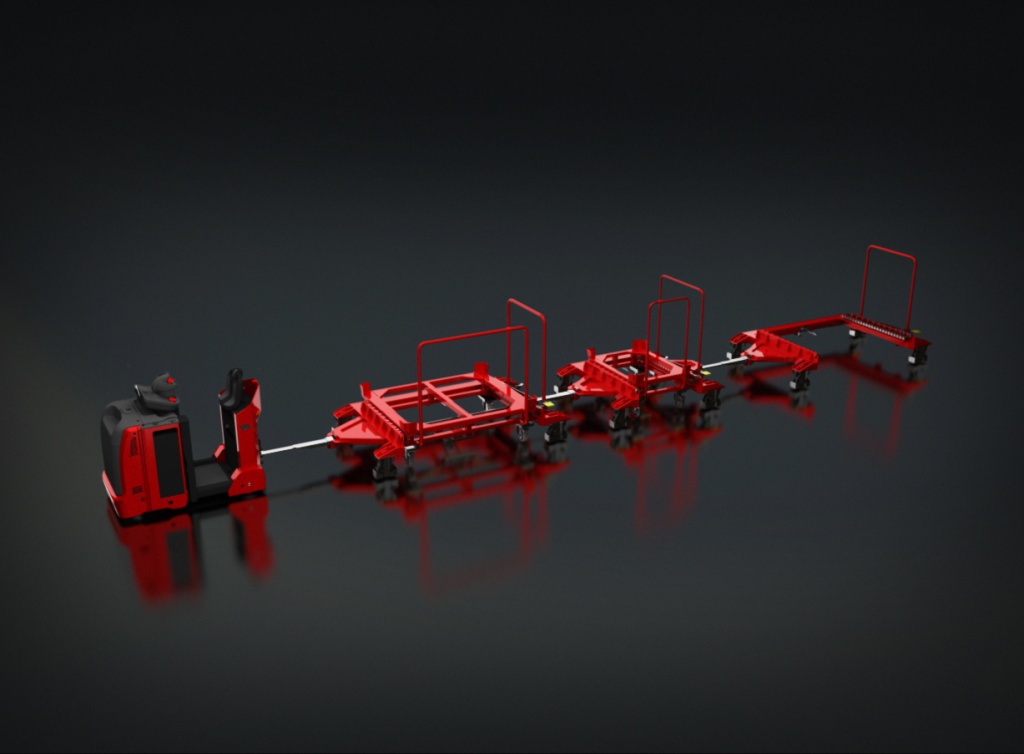

Also basic technical parameters of target transport sets were defined:

– expected net load capacity of a trolley: 450 kg;

– expected load capacity of a single platform: 2000 kg;

– the platforms should be suitable for transporting trolleys sized: 840 x 1250 mm, 790 x 620 mm and 2430 x 780 mm;

– maximum number of platforms in a train: 4;

– number of trolleys transported in a single train: 8–16, depending on the size of containers.

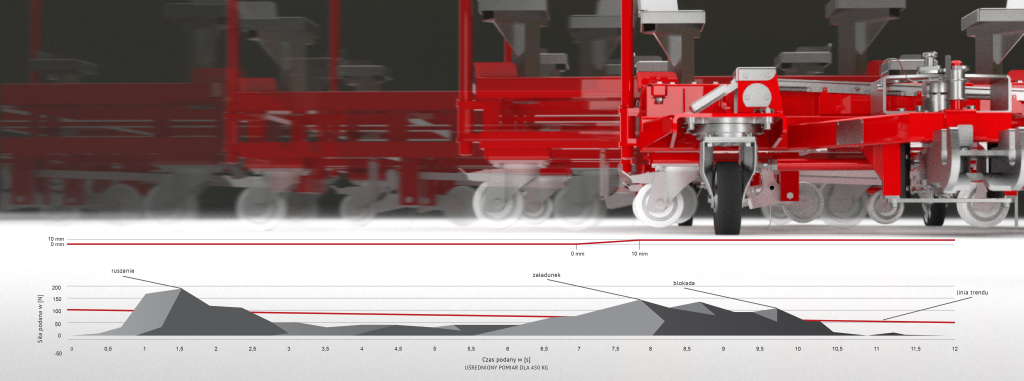

An analysis preceding implementation demonstrated that the way the trolleys functioned together with the platforms was the main cause of both excessive noise generated by transport sets and excessive wear of trolley components.

The trolleys “loosely” occupied the space on a platform during transport, leaving large clearances and impacted each other on the way through bumps and expansion joints existing on their route.

Platforms designed so as to lift trolleys for the time of transport were proposed to solve the problem. The E-LINER® platforms are equipped with roller strips that interact with entrance sections so that trolleys are lifted by the force of inertia to 10 mm above the floor, using a purely mechanical method. Consequently, the trolleys had to be modified and equipped with special entrance sections suitable for functioning together with the old system used by the customer in a transition period of project implementation and with a new system of lean manufacturing production to be implemented.