PACKING AND PICKING ASSIST SYSTEMS

The very rapid increase in production diversity, the number of different components and the significant rotation of the assortment of parts cause that the process of collecting and preparing sets of elements to be transferred to individual production sections is currently one of the major challenges of internal logistics. The time-consuming nature of this process and the potential for faults might be improved by implementation of systems supporting its speed, precision and ergonomics allow significant reduction of commissioning costs.

COMMISSIONING AND COMPLETATION SUPPORT SYSTEMS

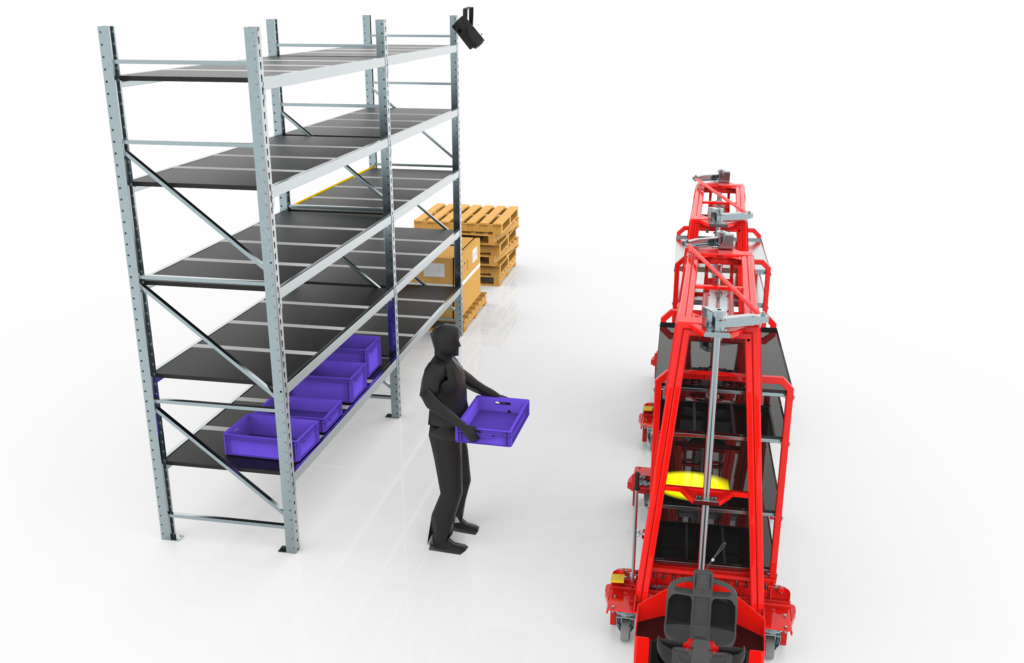

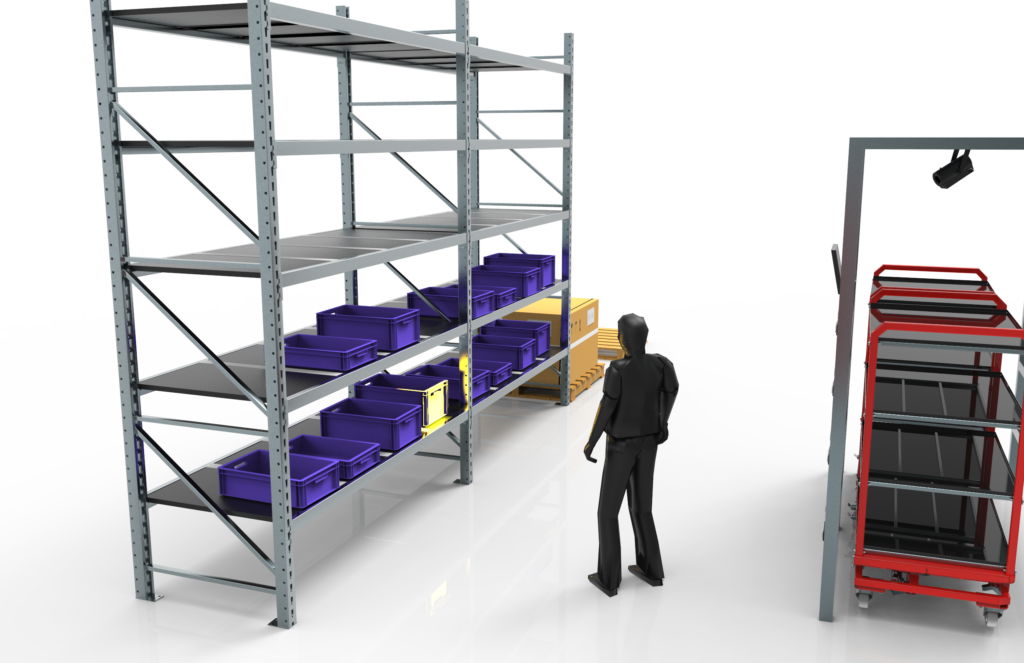

Pick-by-Light / Put-to-Light

THE PROCESS OF COMMISSIONING PROCEDURE

Indication of materials to be picked is shown by a mobile light source that illuminates the storage socket. Information on the quantity

and characteristics of items (name or color) can be transmitted through central displays. Correct part pickup is confirmed and corrected by the indicator lights and acknowledgment buttons.

The entire process is displayed on ASi-5 compartment displays and ASi-5 eTag display modules.

The main advantages of the Pick-by-Light / Put-to-Light system:

• Easy configuration and a wide range of applications

• Increase efficiency and cost savings by eliminating paper documents in the picking process.

• Elimination of mistakes according to the principle of preventing mistakes named Poka-yoke.

• Low downtime thanks to low-maintenance technology.

• Low investment costs and simple installation.

• Fast amortization.

• Low maintenance costs.

• Simple and easy system operation.

• Possibility of integration with WAMECH intralogistics systems

INTEGRATION WITH TRANSPORT SYSTEMS

Thanks to the use of the Pick-by-Light / Put-to-Light system, it is possible to quickly and correctly complete the parts necessary for delivery to individual production stations. Faster deliveries – thanks to the optimization of the picking assist process, it is possible to prepare subsequent sets of parts faster. Increased work ergonomics – the elimination of the need to search for individual parts and verify them with a printed list allows for intuitive and error-free order picking.

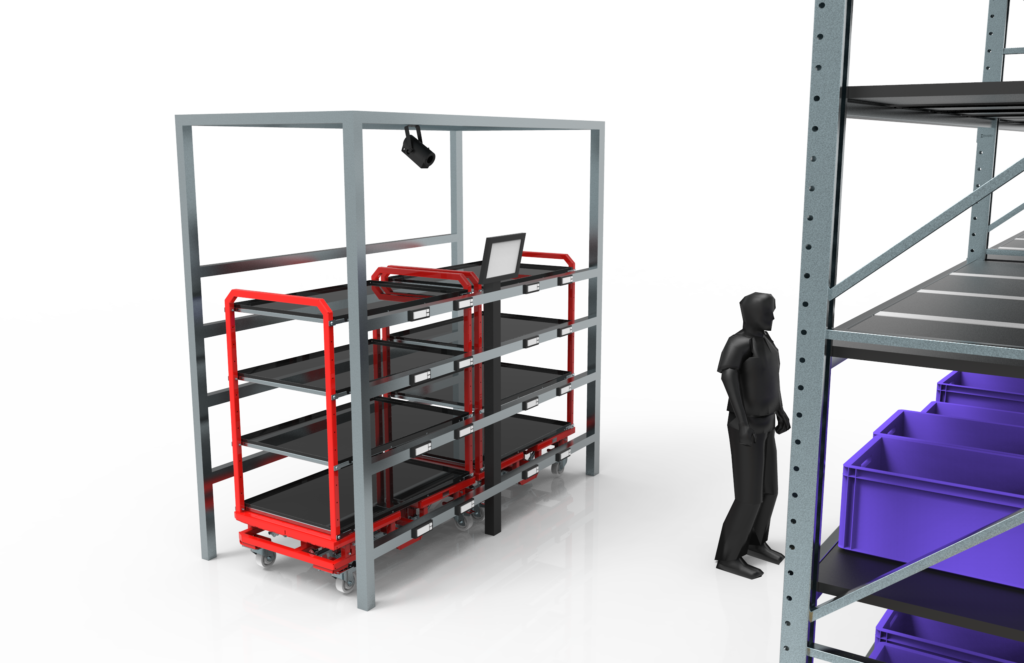

IntelliCart

SYSTEM CHARACTERISTICS

The intelligent IntelliCart order picking truck uses signaling technology to increase efficiency in the parallel picking of multiple orders. It is equipped with its own control software as an interface to peripheral systems and ERP systems. All display devices are part of the trolley, so no additional components are required.

SYSTEM DESCRIPTION

Thanks to IntelliCart trolleys, an employee can complete up to 40 orders simultaneously. They are used in complex deployments that require high bandwidth and have a number of subprocesses. They have been designed for maximum picking efficiency with 600 pickings per employee and hour. The software can manage 40 different orders in parallel.

Every command in the order picking process is displayed on the LED strip and the MiniMaster display. A sensor monitors that the product is properly picked up. The next download location is not displayed in case of a mistake. Only the correction of the error enables the continuation of the process. In addition to the monitoring sensors, barcodes or confirmation buttons can also be used. Confirmation of the last collection of a given product activates information about the next warehouse location to which the employee is to go.

The main advantages of IntelliCarts:

• Improving the quality and speed of picking or sorting

• Enabling the completion of multiple orders at the same time

• Optimal use of equipment

• Resistance to errors thanks to the use of a process based on the Poka-yoke principle

• Flexible and quick change of display location depending on the needs

• Possibility of integration with WAMECH intralogistics systems and Redge’s AGV

IntelliPick

SYSTEM DESCRIPTION

The modular IntelliPick control software forms the basis for efficient picking and order-picking processes. With its help, you can develop the most effective and efficient process concept. It acts as an interface for warehouse management or ERP system. Receives and processes order data in real time. It controls all operations of the pick-by-light system and maps the picking process. This includes operator registration, every picking process, and special functions like warehouse operations and corrections. Due to its modular software structure, it can be combined with various data interfaces. The system is configured on the MiniMaster touch display.

The main advantages of the IntelliPick system:

• Significant improvement in ergonomics and speed of picking or sorting

• Full real-time data synchronization

• Short implementation time

• Compatibility with other picking systems

• Low level of investment

• Possibility of integration with WAMECH intralogistics systems and Redge AGV’s