EFS WORKING STATIONS

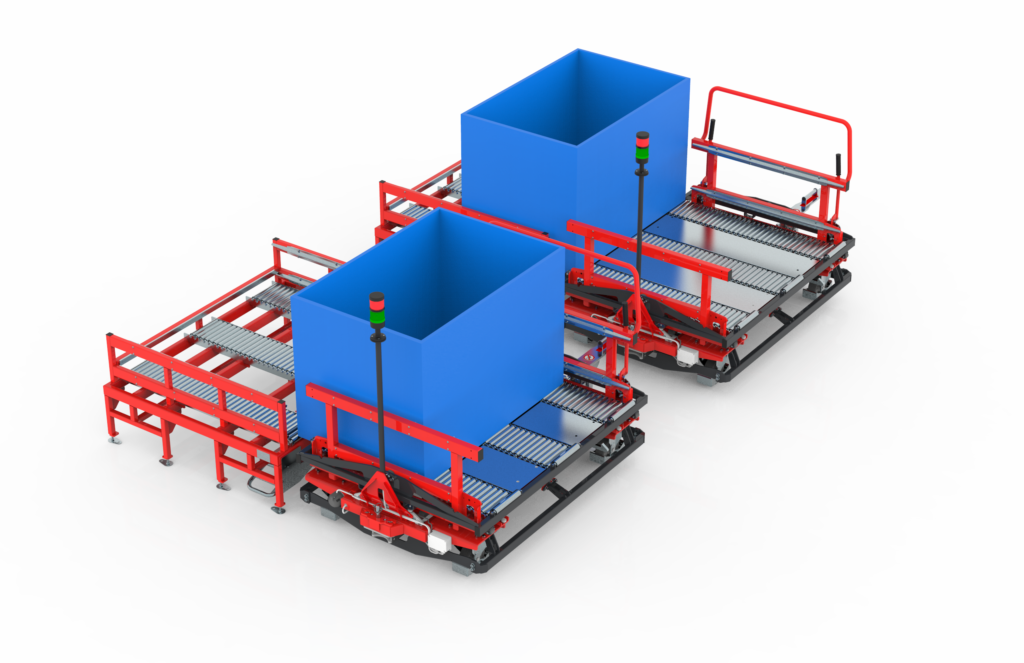

In order to unload containers delivered by EFS platforms, we have designed special workstations that cooperate with them. EFS working stations allow you to transfer containers off the platform to the station’s sockets without the need of using the train operator’s muscles. Furthermore, they allow for increased safety by separating the internal transport section from the assembly sections of production plant. Another aspects are the ability to buffer material at the production line and the ease and ergonomics of container exchanging.

STATIONS CHARACTERISTICS

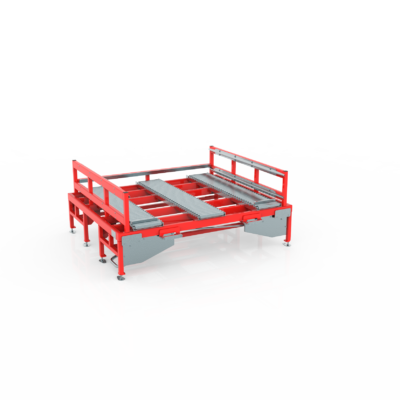

EFS station - one socket

Code: AI.1606

Overall dimensions [mm]:

Width: 1470

Length: 1260

Height: 630

Dimensions of working space [mm]:

Height of platform: 380

Maximal number of containers in station: 1

Technical parameters:

Max weight of container [kg]: 1000

Net weight [kg]: 250

Cooperation with containers of dimensions [mm]: 1200×800, 1200×1000

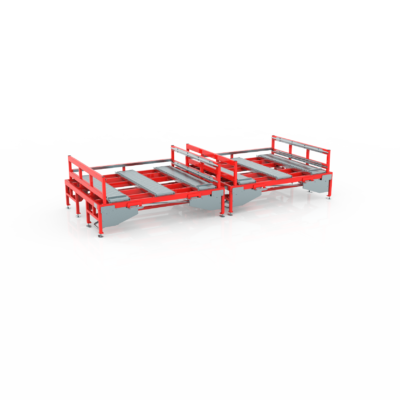

EFS station - two sockets

Code: AI.1607

Overall dimensions [mm]:

Width: 2900

Length: 1280

Height: 1200

Dimensions of working space [mm]:

Height: 380

Maximal number of containers in station: 2

Technical parameters:

Maximum weight of container [kg]: 1000

Net weight [kg]: 500

Cooperation with containers of dimensions [mm]: 1200×800, 1200×1000

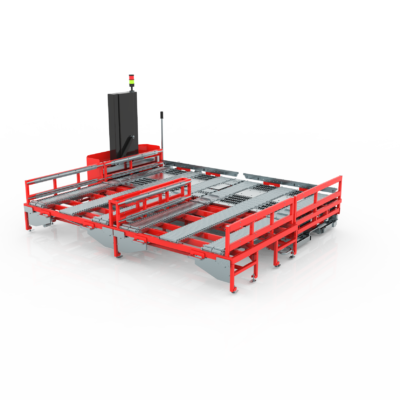

EFS station - four sockets

Code: AI.1602

Overall dimensions [mm]:

Width: 2900

Length: 2550

Height: 1200

Dimensions of working space [mm]:

Height: 380

Max number of containers in station: 4

STATIONS FEATURES

LIFT FOR THE ERGONOMICS INCREASEMENT

Four sockets EFS station may be equipped with additional feature of lifting socket for raising the height of container thus increasing the ergonomics of material picking/loading.

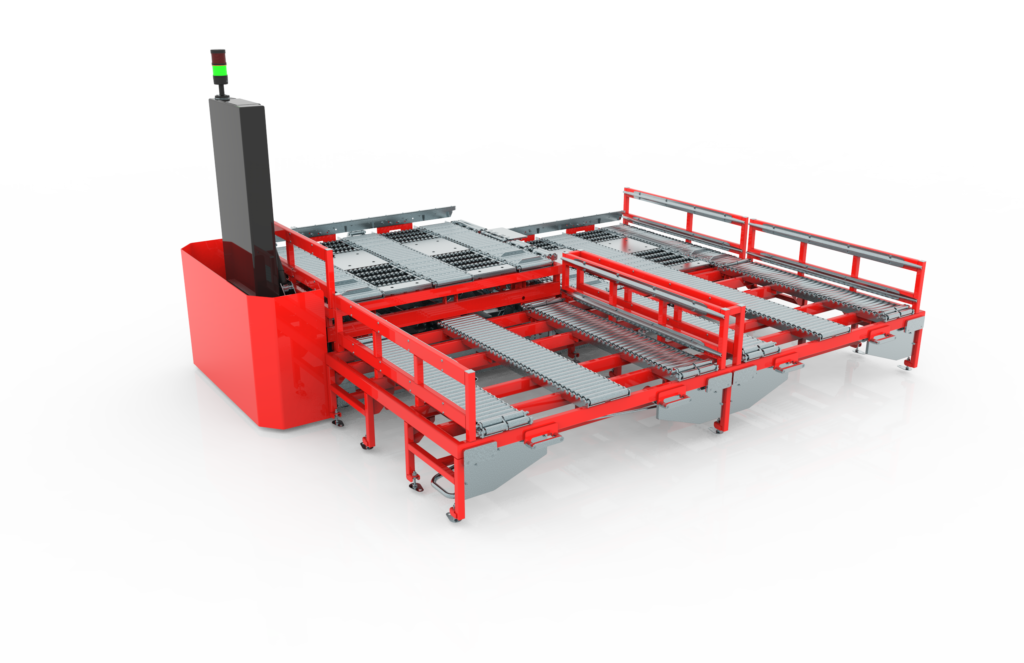

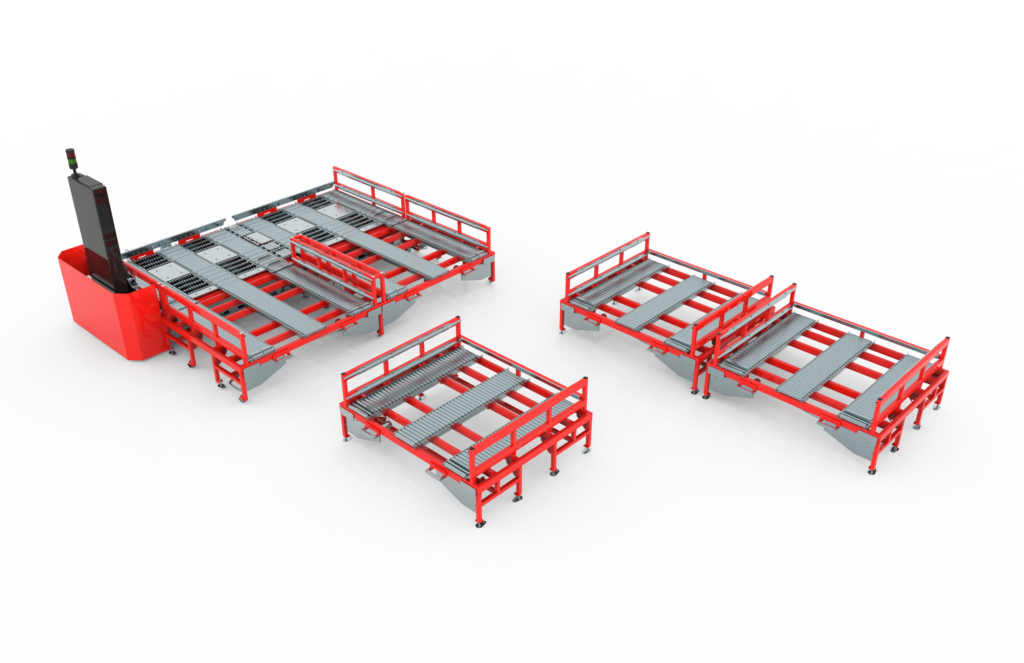

DIFFERENT KINDS OF WORKING STATIONS

Depending on the needs of certain production plant it is possible to assemble either one, two or four socket stations. If required we can also provide the dedicated solution – of other number of sockets or functionalities.

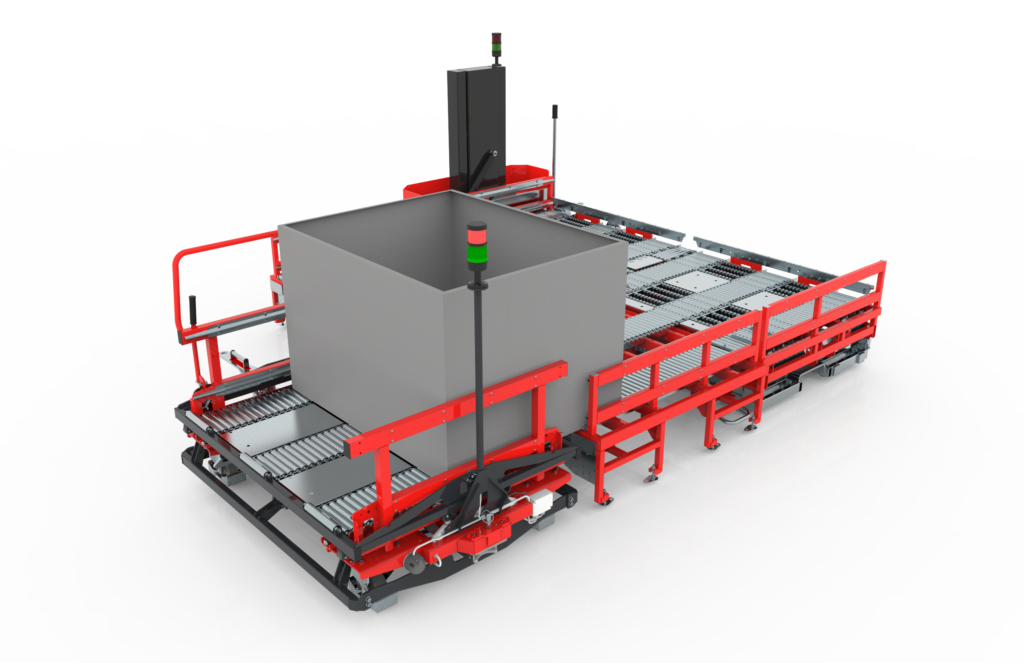

MECHANICAL SYSTEM OF PLATFORM AND STATION CONNECTION

After the logistic train has reached the destination of delivery, it is necessary to connect the platform with the station before unloading. Therefore the EFS system platform has been equipped with clamping mechanism for connecting with station. The connection is being done in a way to ensure full safety of loading and unloading.

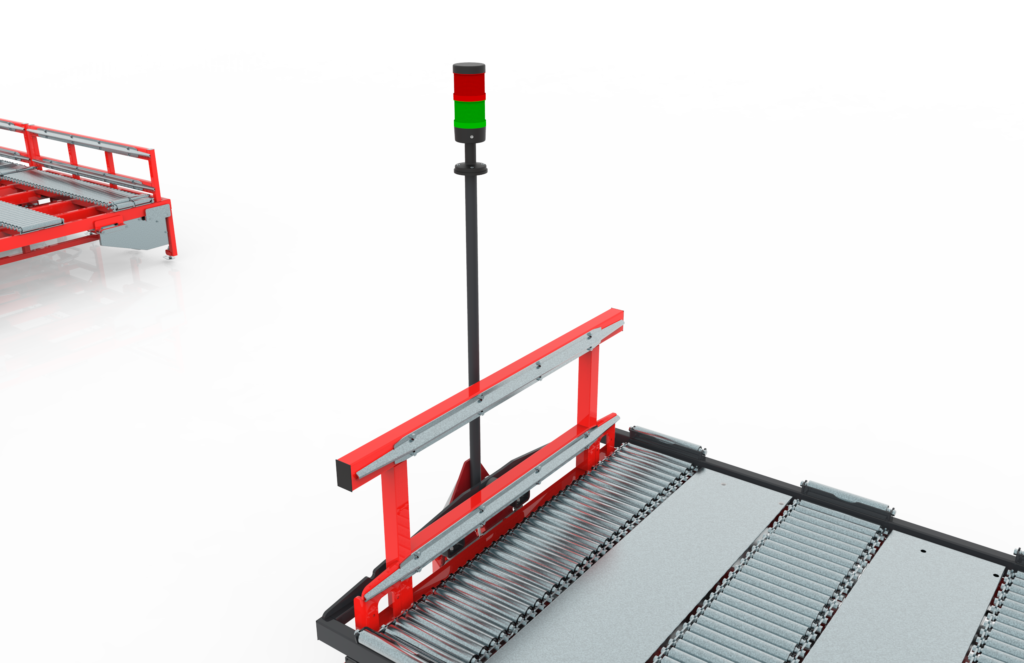

SLS – SAFETY LIGHT SYSTEM

Stations are equipped with a signal lamps which show the information about the current docking status of the containers. Incorrect connection of platform and station or wrong position of the container cause the warning signal to be activated and system blocks the possibility of the lifting or loading/unloading.

EASE AND SPEED OF CONTAINER EXCHANGING

Thank to mechanical solutions of EFS working stations developed by us the exchange of heavy containers goes smoothly and is being done effortlessly.