C-LINER INTRALOGISTICS SYSTEM

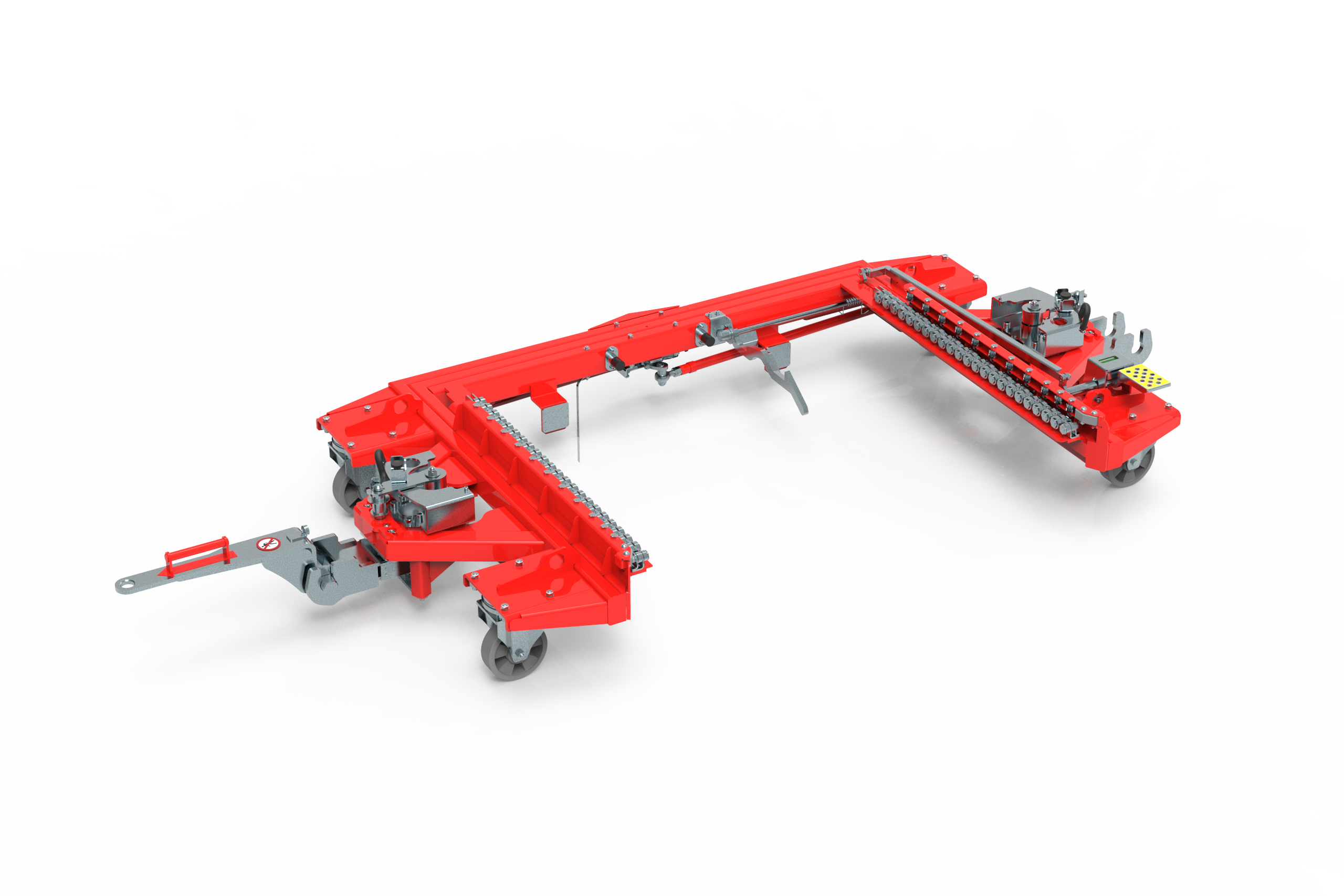

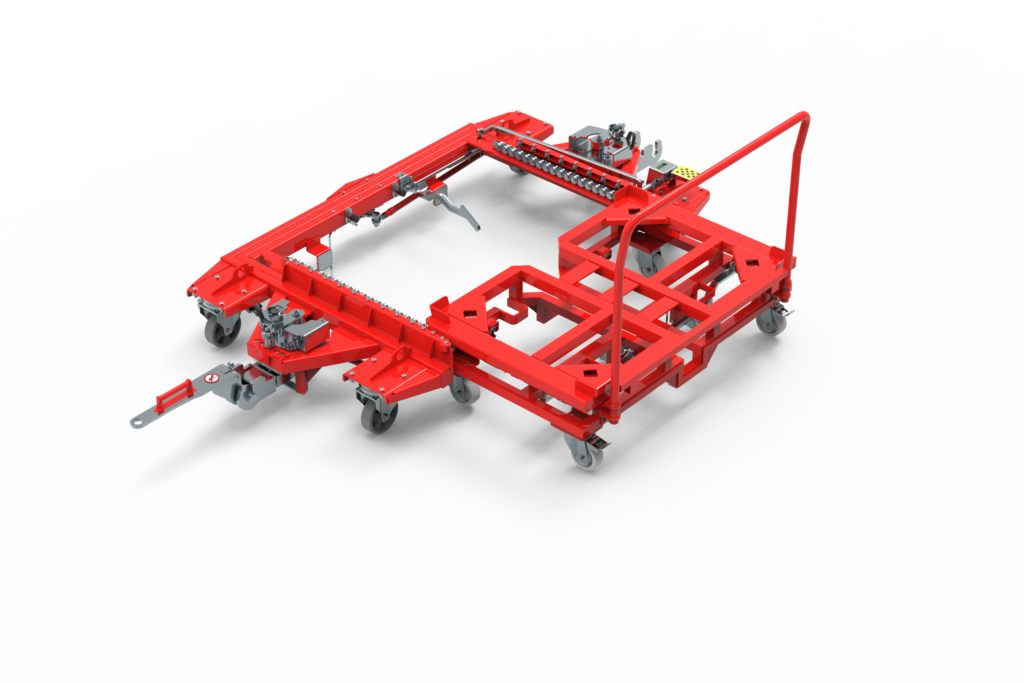

The C-Liner intralogistics system is one of the standard solutions for internal logistics of production plants offered by WAMECH. Like all our products, it characterises by high quality, safety and a wide range of potential applications. Simplicity and reliability – this is how one can briefly define the main advantages of the C-Liner internal transport system. The system includes transport trolleys of various types: GLT, KLT, light, tilt, lift, swing and rotate – all of them cooperate with C-Liner transport platforms. Proper selection of platforms and tailored to the specifics of a given production plant allows for significant optimization of the internal supply chain by both shortening the delivery time of components and reducing empty runs. The large C-Liner frame has an active traction system – four steering wheels controlled by the angle movement of the drawbar, while the small frame has a passive system, which consits of two swivel and 2 fixed wheels.

SYSTEM'S DATA

C-LINER 1200×1000

Dimensions: 2800 x 1060 x 1050 [mm] (l/w/h)

Dimension of containers: 1200×1000, 1200×800 [mm]

Max load of platform: up to 1000 [kg]

Max load of tugger train: 5000 [kg]

Max speed: 6 [km/h]

Max lenght of train: 5 platforms

Turning radius: 2,7 [m]

Turning circle diameter: 5,4 [m]

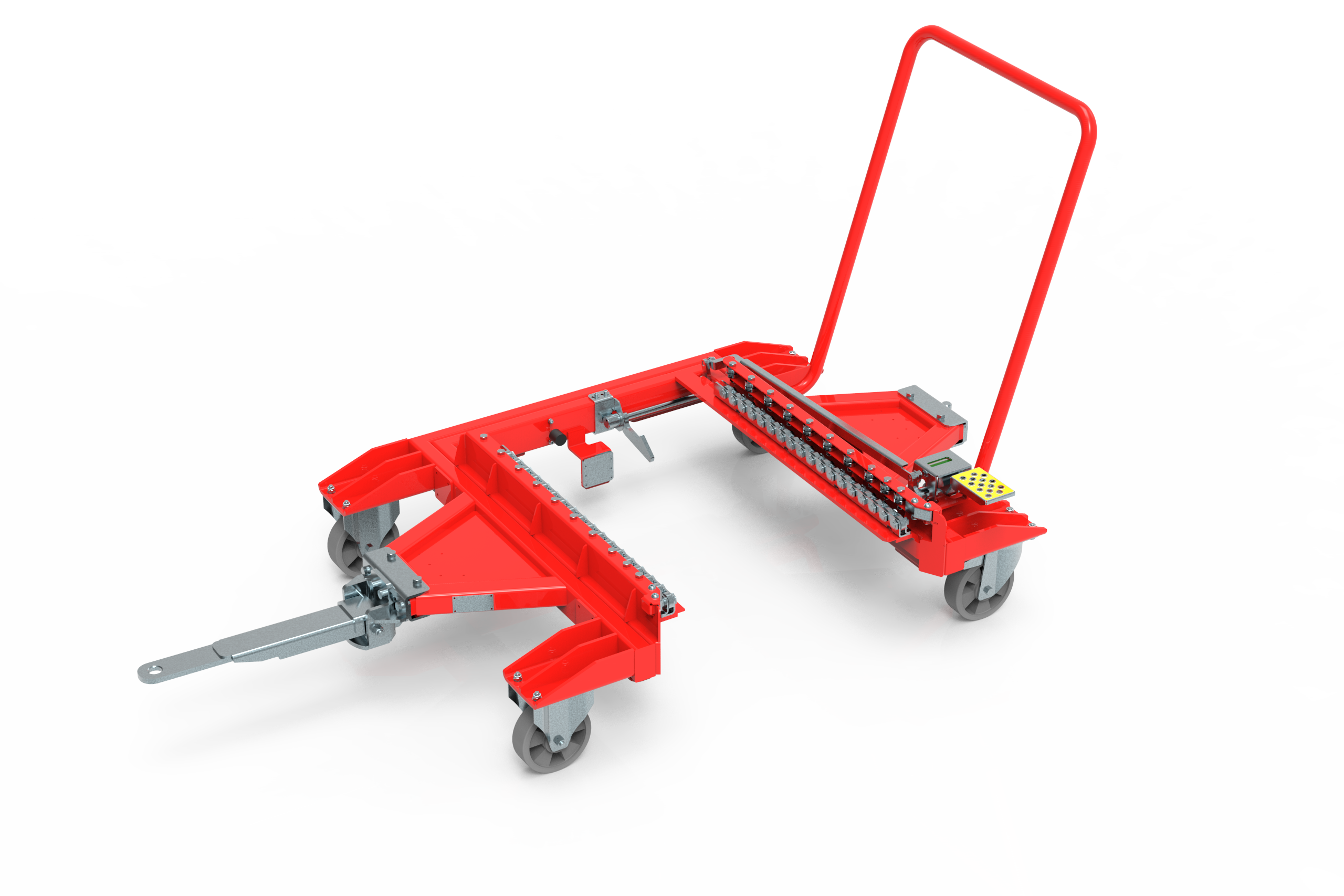

C-LINER 1000×600

Dimensions: 1500 x 1130 x 360 [mm] (l/w/h)

Dimension of containers: 1000×800, 800×600 [mm]

Max load of platform: up to 500 [kg]

Max load of tugger train: do 2500 [kg]

Max speed: 6 [km/h]

Max lenght of train: 5 platforms

Turning radius: 2,7 [m]

Turning circle diameter: 5,4 [m]

CHARACTERISTICS

FULLY MECHANICAL SOLUTION

C-Liner intralogistic system does not need any kind of power supply to run. There are no pneumatics, neither hydraulics nor electrical powered devices in our products.

Low failure rate – all solutions are fully mechanical so that our cart and trolleys system has a very low breakdown rate

Easy to service – mechanical solutions allow carrying out repairs within the production facilities, by your employees trained by our staff.

No mandatory certification – our products are not subject to the Machinery Directive , which means that do not involve additional costs for mandatory certification of vehicles.

Increased security – as opposed to hydraulic solutions , there is no risk of an oil leak that could lead to a dangerous train and platforms slippage.

MAX SPEED 6 KM/H OR 10 KM/H

Our system used in tugger train can be driven with the speed limit of 6 km/h – for the small C-Liner equipped with passive steering system or even 10km/h for large C-Liners which have the active steering system.

Quicker supplying – thanks to our trolleys and platforms it is possible to ensure fast material handling in safe way.

INDEPENDENCE OF USED TRACTOR

There is no certain towing truck bound to our C-Liner intralogistic system – it can be used freely with any kind of tractors. Platforms can cooperate with any tractor’s brand.

Adaptation – no matter of truck’s producer used in facilities our platforms and and trolleys will fit them

Elasticity – there are no restrictions in taking up the decisions in scope of trucks purchase

PASSIVE OR ACTIVE TRACTION SYSTEM

The C-Liner intralogistics system small platform is equipped with two swivel and two fixed wheels, the large C-Liner frame has a active traction system or four wheels steered by the angle movement of the drawbar.

PATENTED

Our system uniqueness is confirmed by the patent rights.