V-LINER

V-Liner is one of the standard systems for internal logistics transport which is being offered by Wamech. As all of our products its characteristics are high quality, safety and also a multipurpose use. Its biggest advantage is a possibility for loading/unloading the material on both sides among the route. System consists of transport platforms in two sizes, many different trolleys and turntables.

SYSTEM'S CHARACTERISTICS

V-LINER 1200×1000 [mm]

Dimensions: 2900 x 1120 x 2150 [mm] (l/w/h)

Dimension of packages: 1200×1000, 1200×800 [mm]

Max load of platform: up to 500 [kg]

Max load of tugger train: up to 2500 [kg]

Max speed: 6 [km/h]

Max lenght of train: 5 platforms

Turning radius: 3 [m]

Turning circle diameter: 6 [m]

V-LINER 1000×600

Dimensions: 1500 x 1120 x 2100 [mm] (l/w/h)

Dimension of containers: 1000×600, 800×600 [mm]

Max load of platform: up to 500 [kg]

Max load of tugger train: do 3000 [kg]

Max speed: 6 [km/h]

Max lenght of train: 6 platforms

Turning radius: 2,7 [m]

Turning circle diameter: 5,4 [m]

UNIQUE FEATURES

FULLY MECHANICAL

V-Liner same as all of the other products designed by Wamech do not require additional power supply. There are no pneumatic, neither hydraulics nor electric devices in the platform. It is just and only mechanical – which is a great advantage.

Easy service – simple, mechanical give a possibility to exchange almost every broken part of platform in no time

Low failure rate – mechanical means really reliable

No need of certification – our products are not being classified as a machines therefore there is no mandatory certification in that scope, so you don’t have to spend the money and time

Increased safety – no hydraulics means no oil leaks which are causing severe danger for the internal transport

Much lower exploitation costs – no need of power supply, high reliability and durability, no certification, inspections, services all these characteristics means one thing: you will save lots of cash while using our platforms.

MAXIMUM SPEED OF 6 KM/H

Being high and wide structures our A-frames are still capable to be transported with a decent speed.

Quicker supply – times is money so the quicker material is handled the more you gain

COMPATIBILITY WITH ALL TRACTORS

All of the tugger train tractors being sold on market can be used together with our platforms. We not only do not limit the possibilities we widen them.

Elasticity – we do not want you to buy or use a certain type on tractor – we let you decide what fits you the best. We can assure you though that with our platforms you will see the real potential of tugger train material handling systems.

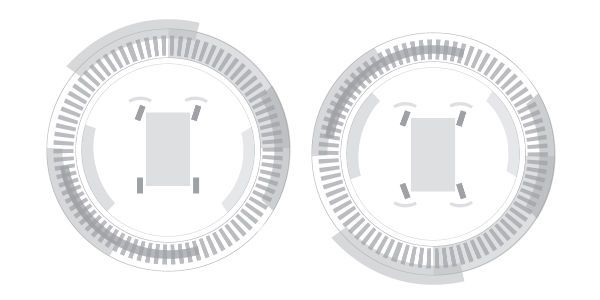

PASSIVE AND ACTIVE TRACTION SYSTEM

Depending on the size of platform the smaller is equipped with passive traction and the bigger one is having active wheels system. Both solutions are perfectly fitting the platforms needs so the are reliable and retain the tractor’s route.

Reliability – both systems are fully mechanical solutions so the failure rate is really low

Traction – platforms retain the route of pulling equipment so there is no risk of excessive corners cutting while turning

TILT TROLLEYS

Our V-Liner a-type frames can be used also with our special tilt trolleys. That means you not only can load and unload the trolley on both sides but also you can increase the ergonomy of unloading the material on the production section.

PATENT RIGHT

Mechanical solutions used in the system are unique – and they had been patented by our company.