TRACKING, CONTROL AND REPORT SYSTEMS

Real-time locating system ( RTLS ) provides knowledge of the exact position of logistic trains and operators at a given moment of time, but also, if necessary, of any platform or even a trolley. Based on previously collected data, RTLS allows you to analyze traffic and enables identification and elimination of workflow bottlenecks, saving time and money. The navigation and tracking functions allow constant supervision of all monitored objects. The logistics process becomes faster and smoother – thanks to optimization made on the basis of previously collected data. Different technologies can be used to collect and transmit it in real time – based on the emission and reception of radio waves, infrared or ultrasound waves. The selection depends on the system’s requirements and the possibility of its implementation on the premises of a given production plant.

KEY BENEFITS FROM THE INTRODUCTION OF THE RTLS SYSTEM

TRACING, COLLECTION AND TRANSMISSION OF DATA

It allows full control over the course of the logistics process – data is collected

and aggregated in real time, which allows you to quickly draw conclusions

and introducing possible improvements and, as a result, cost optimization.

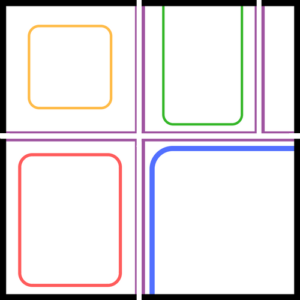

CONTROL OF ACCESS TO ZONES

Thanks to RTLS it is possible to monitor individual zones – warehouse, trolleys or employees

using tags. These zones are not physically visible, but if a person enters them, the program

automatically starts registration and tracks movements. This allows for increased safety and

reducing the risk of accidents by accurately predicting possible collisions of resources in real time.

SPEED CONTROL AND ACCIDENTS PREVENTION

Safety is one of the priorities of the production plant.

The RTLS system can be used to control and control the speed of the trucks in order

increase safety. The program assesses, for example, that the trolley moves too fast

in the controlled zone and automatically slows it down. It can also predict collisions and prevent

them by stopping the trolley before a potentially dangerous incident occurs.

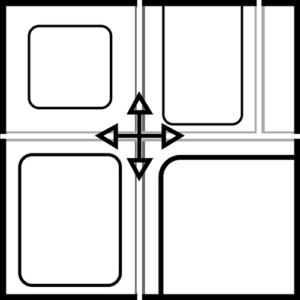

NAVIGATION AND DECISIONS SUPPORT

The RTLS system can help you automatically identify and track the location of a particular employee / trolley and send the corresponding task directly to it – e.g. information on loading or unloading at a specific production section. What’s more, operators are up to date on the consumption of components on each individual sections. Also in the event of a blockage on a given path, the tugger train may be automatically directed to another route in order to reduce the delivery time.