THE STANDARDIZED E-LINER SYSTEM FOR THE UNITED STATES

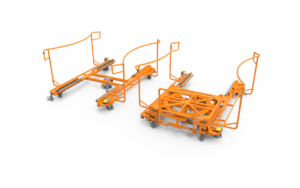

With a view to manufacturing plants located in the United States, we have developed a system that meets their needs. The system includes platforms, trolleys, and turntables – cooperating with each other and giving a wide spectrum of possibilities in the field of material transport on the premises of production plants.

BASIC SYSTEM PARAMETERS

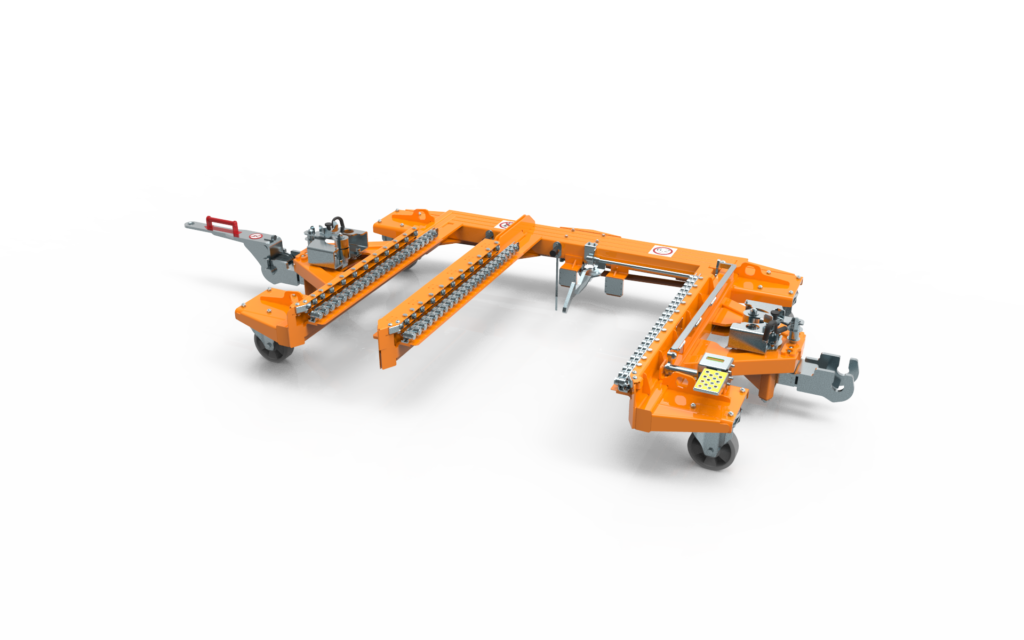

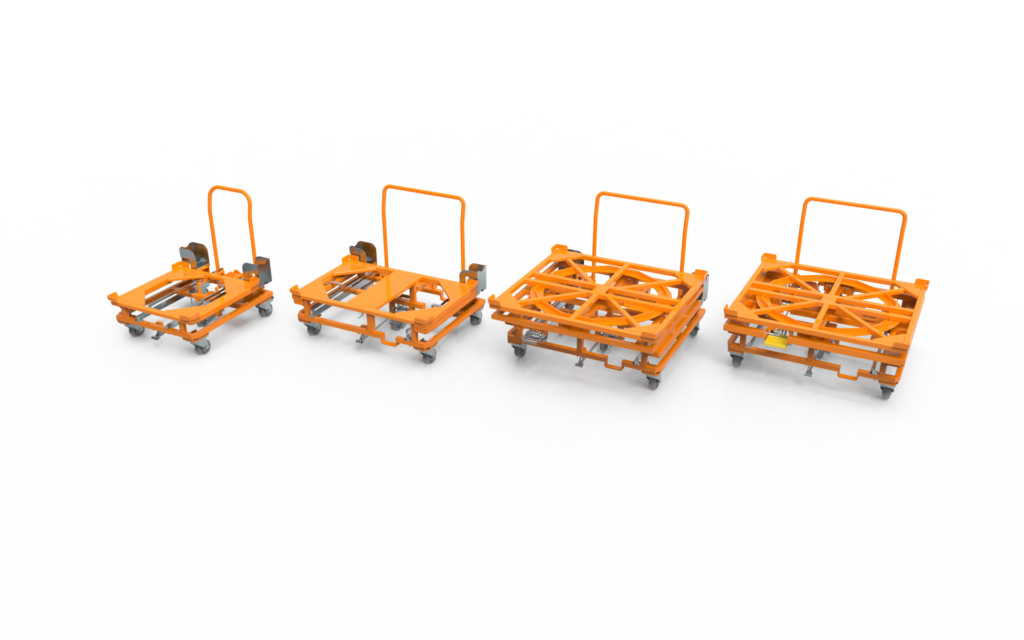

E-LINER AE.1301.V4 PLATFORM

Dimensions: 117″ x 55″ x 15″ (lenght/width/height)

Platform max load: 2425lb

Tugger train max load: 11023lb

Platform net weight: 816lb

Max speed: 6mph

Maximum lenght of tugger train: 6 platforms

Turning radius: 59″

Turning circle diameter: 118”

Suggested width of routes: 79″

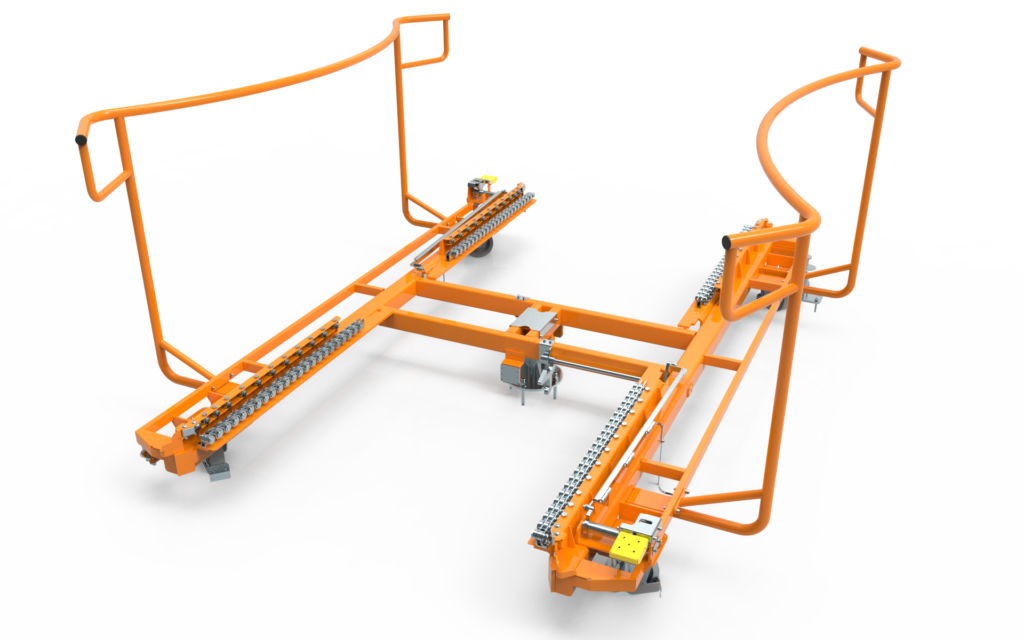

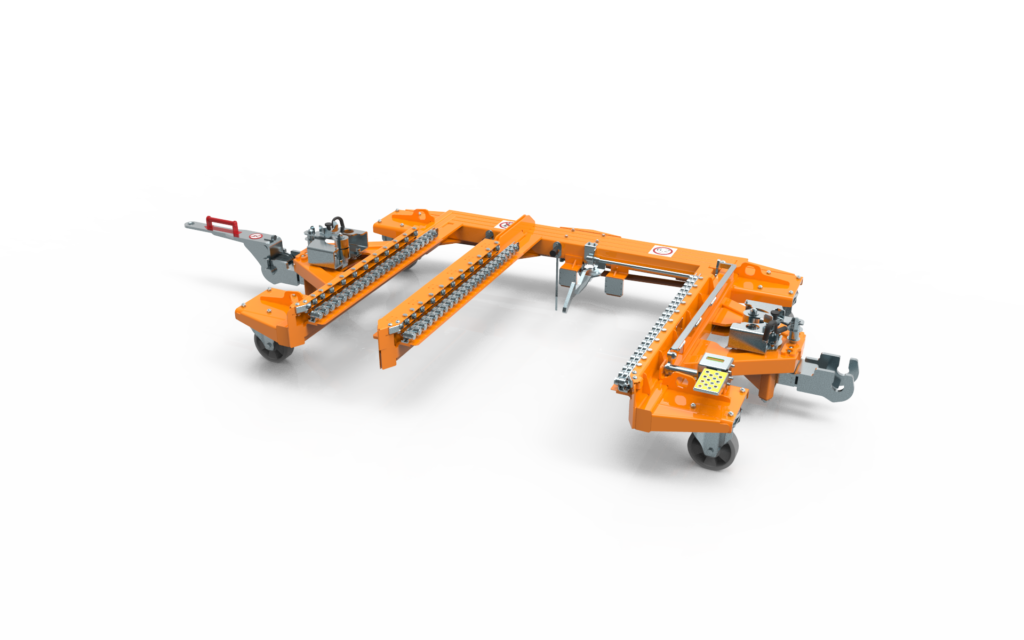

OBROTNICA AE.1371.V14

Dimensions: 109″ x 91″ x 48″ (lenght/width/height)

Width between side rolls: 48″

Net weight: 618lb

Turn diameter: 134″

Max number of trolleys: 2 szt.

Max load: 2976lb

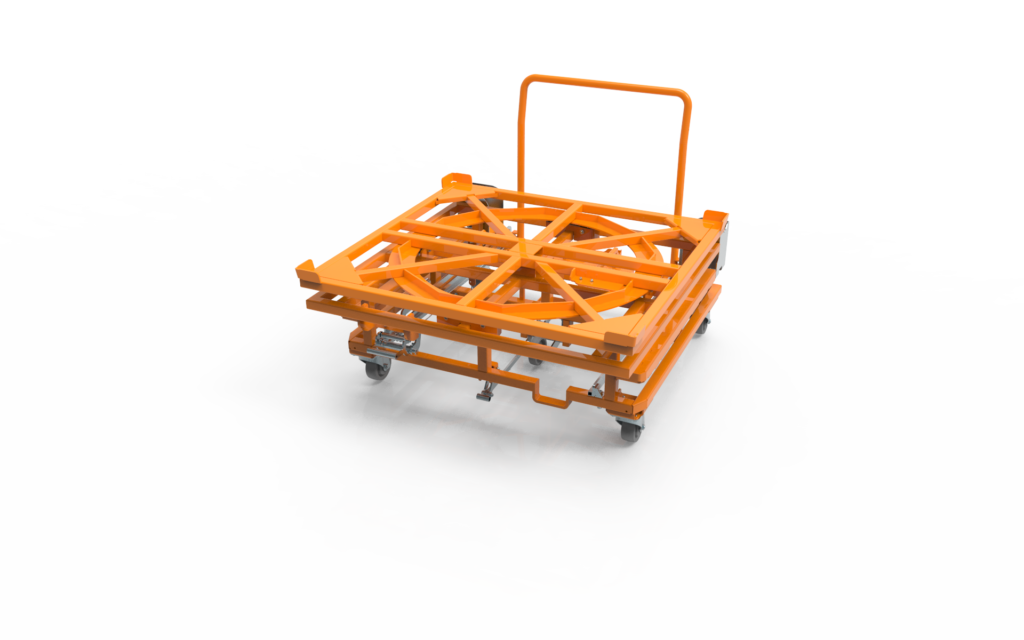

AE.1302.V129 TROLLEY

Dimensions: 56 “x 50” x 41 “(length / width / height)

Dimensions of the working space: 46 “x 49”

Capacity: up to 1984lb

Net weight: 462lb

Maximum speed in manual transport: 2.5mph

Height of the transport platform: 23 “

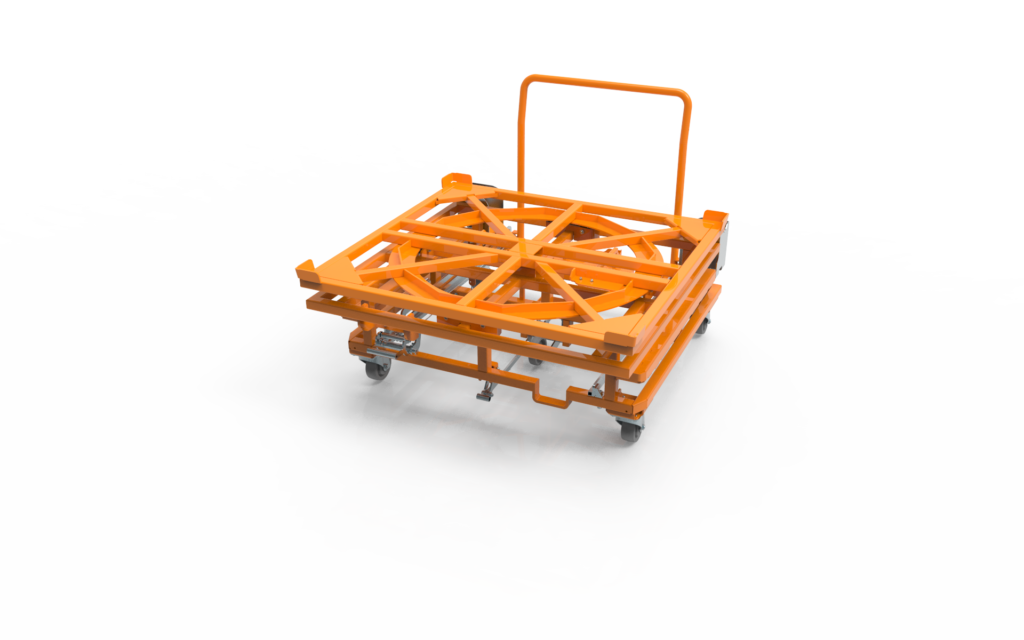

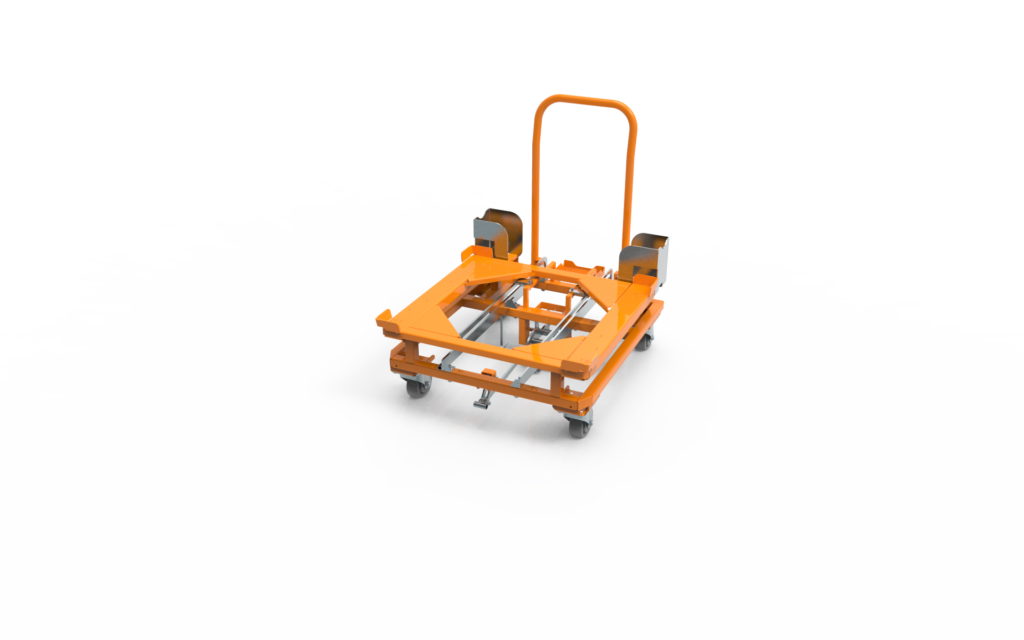

AE.1302.V131 TROLLEY

Dimensions: 51 “x 50” x 41 “(length / width / height)

Dimensions of the working space: 46 “x 49”

Capacity: up to 1984lb

Net weight: 462lb

Maximum speed in manual transport: 2.5mph

Height of the transport platform: 19 “

AE.1302.V47 TROLLEY

Dimensions: (length / width / height) 33.6 “x 42.6″ x 14.2 ”

Dimensions of pallets / containers: 32 “x 30”

Capacity: [lbs] 2000

Net weight: [lbs] 200

Maximum speed in manual transport: [m / h] 2.5 mph

AE.1302.V48 TROLLEY

Dimensions: (length / width / height) 48.9 “x 41.3″ x 16.2 ”

Dimensions of pallets / containers: 48 “x 31”

Capacity: [lbs] 2000

Net weight: [lbs] 220

Maximum speed in manual transport: [m / h] 2.5 mph

UNIQUE FEATURES

FULLY MECHANICAL SYSTEM

The internal transport system for production plants E-Liner does not have solutions based on pneumatics, hydraulics or electric power. The system operates based only on mechanical solutions.

Low failure rate – all solutions are fully mechanical so that our cart and trolleys system has a very lowe breakdown rate

Easy to service – mechanical solutions allow carrying out repairs within the production facilities, by your employees trained by our staff.

No mandatory certification – our products are not subject to the Machinery Directive , which means that do not involve additional costs for mandatory certification of vehicles.

Increased security – as opposed to hydraulic solutions , there is no risk of an oil leak that could lead to a dangerous train and platforms slippage.

Significantly lower operating costs – no need for additional power , low failure rate , no need maintenance translate into very low use of the system. E-Liner production transport is the epitome of a vision of lean manufacturing – providing cost effective manufacturing solutions.

MAXIMUM SPEED 6 MPH

E-Liner tugger train might be driven with the maximum speed of 6 mph (applies to the straight sections).

Faster delivery – thanks to our carts and platforms, you can safely transport material in production halls faster.

Innovative traction system – thanks to the unique, mechanical chassis, it is possible to maneuver without any problems even on narrow paths

INDEPENDANCE OF TOWING TRACTOR’S BRAND

Our internal logistics solution has been designed with the possibility of being used with different kinds of trains producers. We do not force you to buy and use some certain solution – no matter what kind of brand you use you can be sure that our system will do the job.

Adaptation –regardless of what type trains are used in the manufacturing plant our platforms and carts will fit them perfectly

Flexibility – there are no restrictions regarding trains purchase decisions – choose anything you want and we will provide you our system to make it work!

ACTIVE TRACTION SYSTEM

E-Liner platforms have a unique running system consisting of four swivel wheels cooperating with each other. The developed solution allows moving the platforms along the route determined by the tractor. The angular displacement of the drawbar causes simultaneous movement of all wheelsets on the platform. The developed solution is additionally fully mechanical and reliable.

Reliability – traction and steering solutions are fully mechanical and therefore exceptionally durable

Perfect traction – wheels steered by drawbar give the excellent traction and retain the tractors movement path perfectly

TROLLEY FITTED TO THE US MARKET

We have designed standard trolleys for the E-Liner plaftorm that meet the dimensional and functional expectations of our customers.

TURNTABLES

Turntables are the newest solution supporting internal logistics. It is used to transfer (buffer) cargo in containers on the production section. The turntable is fixed to the ground with specially designed rotating feet which allows rotating for 180 degrees. The use of turntables opens up the new opportunities for manufacturing plant such as organizing the production line according to the FIFO or implementation of sequence assembly.

Optimization of material handling – thanks to the use of turntables it is possible to better manage the time of deliveries of components/materials for specific production sections.

Safe loading/unloading – turntable allows to deliver the container right at the production section without the need of getting to close to it.