E-LINER

E-Liner production transport is the widest spreaded over the World and innovative lean solution dedicated to internal logistics. Its characteristics are: wide scope of use, great traction abilities, cooperation with different kinds of trolleys and containers and very high level of both quality and user safety. The system consists of tugger train trolleys, transport platforms and specially designed turntables which lower the time of containers’ exchange on the production line. E-Liner has been awarded in several contest for its safety, ergonomics and innovative solutions. In 2015 it has been given the main award in the contest for “Innovative Product for Transport, Logistics, Production” which has been hosted by Eurologistics.

SYSTEM'S CHARACTERISTICS

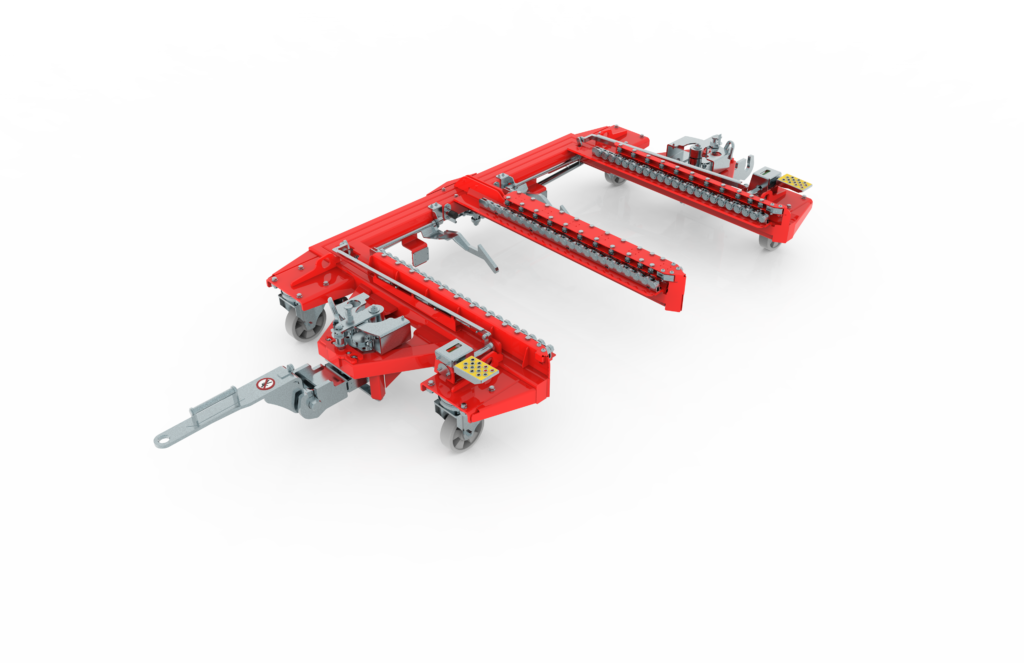

STANDARD E-LINER PLATFORM

Dimensions: 2990 x 1290 x 375 [mm] (l/w/h)

Dimension of containers: 2 x 1000×600, 2 x 800×600, 1200×1000, 1200×800, 1600×1200 [mm]

Max load of platform: up to 1000 [kg]

Max load of tugger train: do 5000 [kg]

Platform’s net weight: 330 [kg]

Max speed: 10 [km/h]

Max lenght of train: 6 platforms

Turning radius: 3 [m]

Turning circle diameter: 6 [m]

SMALL E-LINER PLATFORM

Dimensions: 2990 x 1090 x 375 [mm] (l/w/h)

Dimension of containers: 2 x 1000×600, 2 x 800×600, 1200×1000, 1200×800 [mm]

Max load of platform: 1000 [kg]

Max load of tugger train: 5000 [kg]

Platform’s net weight: 315 [kg]

Max speed: 10 [km/h]

Max lenght of train: 6 platforms

Turning radius: 3 [m]

Turning circle diameter: 6 [m]

UNIQUE FEATURES

FULLY MECHANICAL SYSTEM

Milk run systems supposed to be a lean manufacturing solution and so we have designed our E-Liner production transport. Our platforms and carts do not require any additional power supply. All the systems used are 100% mechanical therefore you lean your production two times – first by implementing the tugger train solution and second time when u have no cost of certification, servicing and power usage.

Low failure rate – all solutions are fully mechanical so that our cart and trolleys system has a very lowe breakdown rate

Easy to service – mechanical solutions allow carrying out repairs within the production facilities, by your employees trained by our staff.

No mandatory certification – our products are not subject to the Machinery Directive , which means that do not involve additional costs for mandatory certification of vehicles.

Increased security – as opposed to hydraulic solutions , there is no risk of an oil leak that could lead to a dangerous train and platforms slippage.

Significantly lower operating costs – no need for additional power , low failure rate , no need maintenance translate into very low use of the system. E-Liner production transport is the epitome of a vision of lean manufacturing – providing cost effective manufacturing solutions.

MAXIMUM SPEED OF TUGGER TRAIN SYSTEM – 10KM/H

After conducting an independent tests which have taken place in production plants of Daimler company, a German certification company DEKRA has committed that E-Liner production system platforms can be used with maximum operating speed of 10 km/h for the straight sections.

Faster deliveries – with our trolleys and platforms material handling in the production plant becomes much quicker

The innovative traction system – thanks to a our unique, mechanical traction chassis it is possible to seamlessly maneuver even on the very narrow paths

INDEPENDANCE OF TOWING TRACTOR’S BRAND

Our internal logistics solution has been designed with the possibility of being used with different kinds of trains producers. We do not force you to buy and use some certain solution – no matter what kind of brand you use you can be sure that our system will do the job.

Adaptation –regardless of what type trains are used in the manufacturing plant our platforms and carts will fit them perfectly

Flexibility – there are no restrictions regarding trains purchase decisions – choose anything you want and we will provide you our system to make it work!

ACTIVE TRACTION SYSTEM

Fully mechanical solution of four sviwel wheels being steered by drawbar allows to retain the towing tractor’s route

Reliability – traction and steering solutions are fully mechanical and therefore exceptionally durable

Perfect traction – wheels steered by drawbar give the excellent traction and retain the tractors movement path perfectly

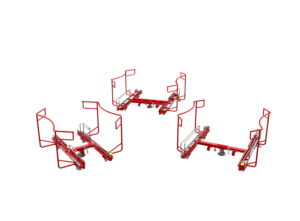

WIDE RANGE OF TROLLEYS

For Liner systems, we have designed many different types and sizes of trolleys that can be used depending on your needs.

Easy unloading – the ability to tilt the cart loaded significantly affects the speed and comfort during emptying

Simplicity and security – with our mechanical solutions use of cart and platforms is intuitive and safe for workers

TURNTABLES

Innovative solution for the production line, affecting the acceleration of replacement of empty containers for full. Turntables also support safety – by separating the zones of: production and internal logistics.

Optimization of material handling – thanks to the turntable it is possible to better manage components delivery time / materials for various production sections

Safe transport – turntable allows for the delivery of the material at the closest possible distance of workstation without neccessity of driving too close

PATENT

The uniqueness of our intralogiistic system confirm not only the above mentioned features but also the patent protection.

The only of its kind our system is unique and none of the our competitor companies do not have the same solutions

Appreciated and rewarded - E-Liner production transport has already been introduced to dozens of factories around the world and was awarded as a device for workplace optimisation improvement